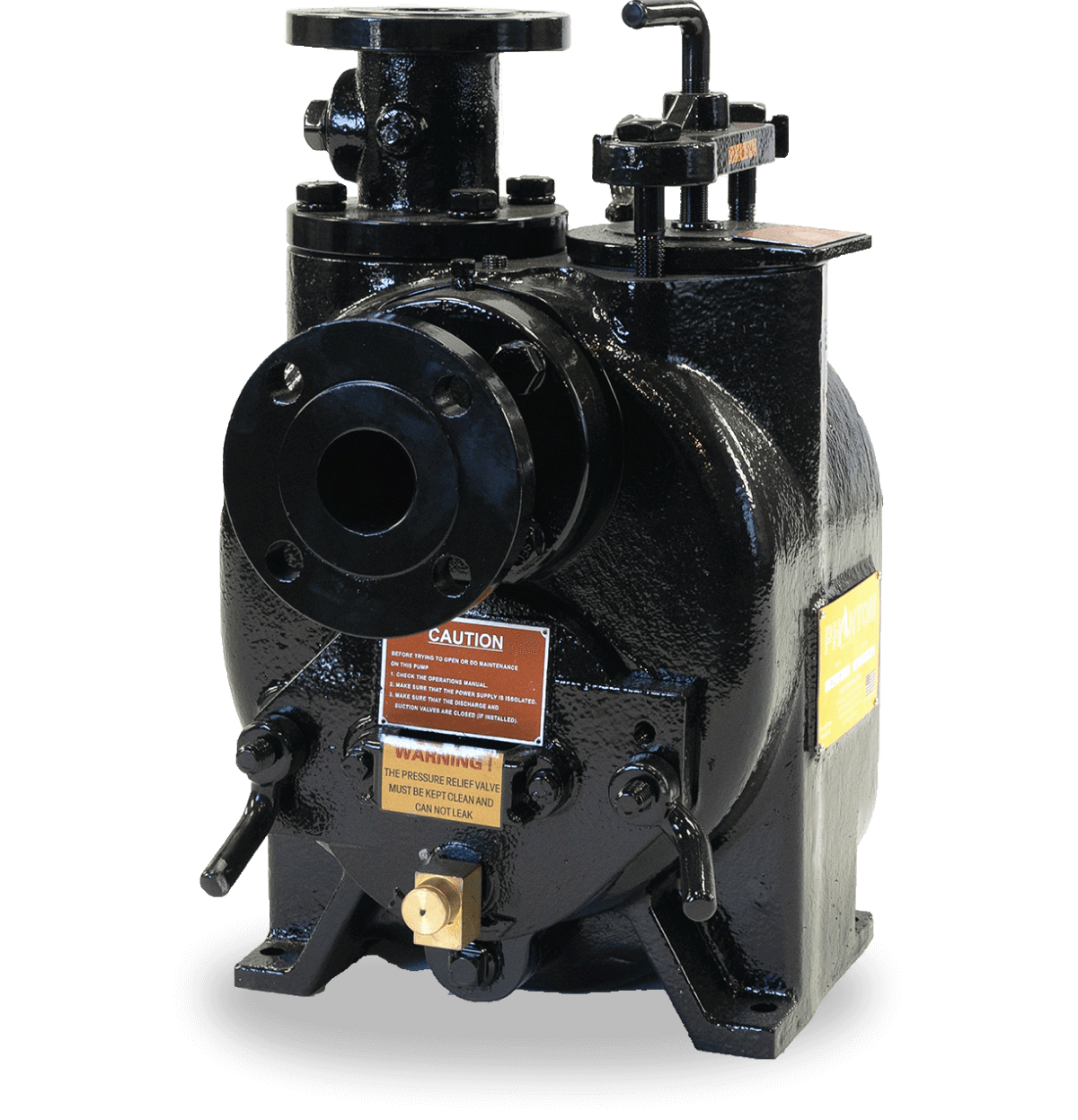

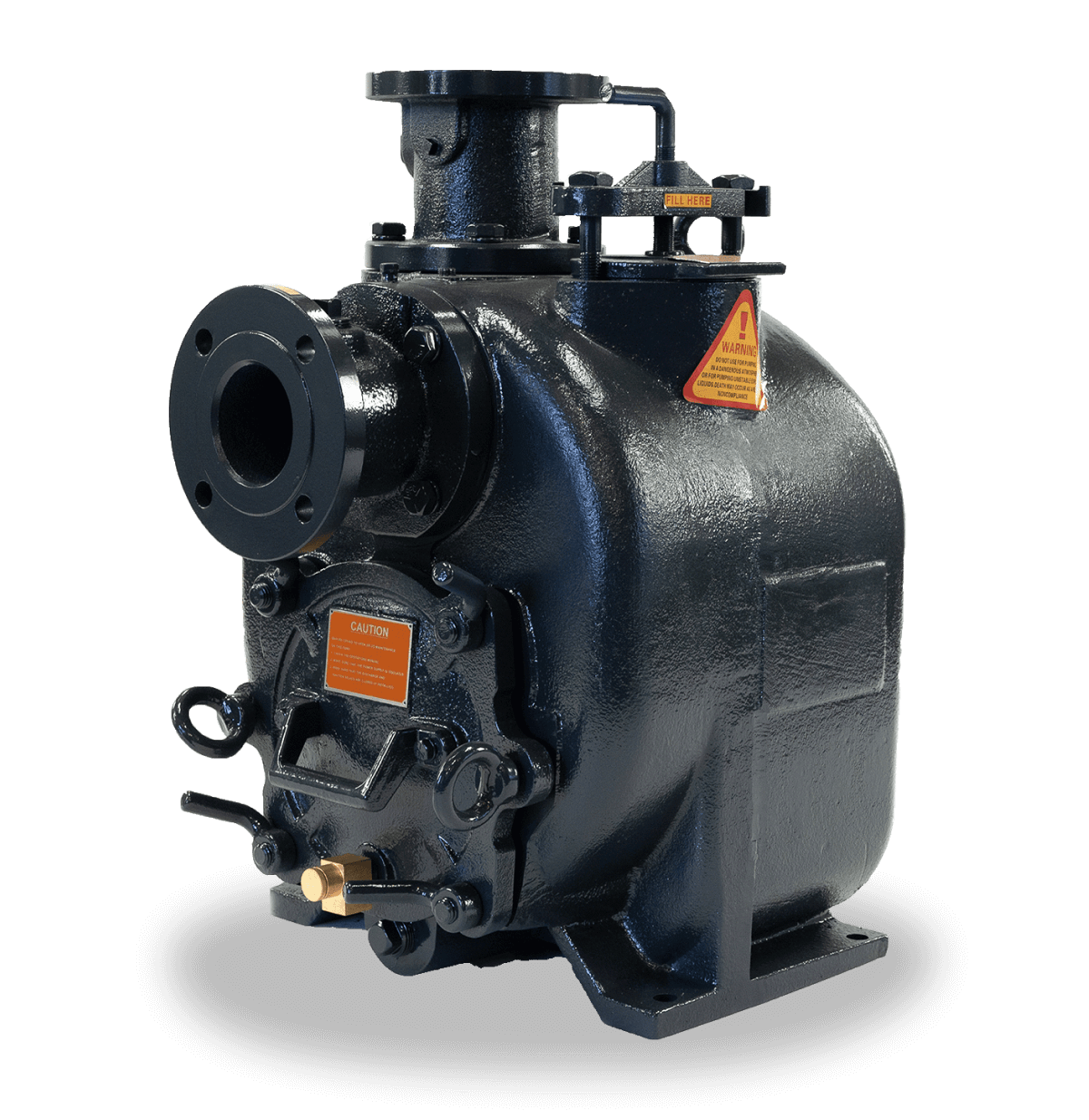

The PL-12 Pump

The PL-12 is a self-priming pump that is suited for a wide variety of applications, including industrial, wastewater treatment, shallow well pumps, fire departments, industrial effluents treatment, and more. This pump is able to fill so many needs because of its ability to fit many flow and pressure specifications and configure to low-pressure settings. So, whether you need a submersible backup sump pump for a mining operation or a dewatering pump for a construction site, the PL-12 is the product for you. Lastly, the PL-12 is interchangeable with other reputable brands, so our customers can rest assured that they will receive an expertly crafted product that will make maintenance and repairs exceptionally simple and cost-effective.

The Benefits & Advantages of the PL-12

With its advanced features and cutting-edge technology, the PL-12 delivers exceptional performance and reliability. One of its key advantages is its remarkable versatility, as it can handle a wide range of fluids, including corrosive chemicals, viscous liquids, and abrasive slurries. This adaptability makes the PL-12 suitable for various industrial applications, ensuring seamless operation across different sectors.

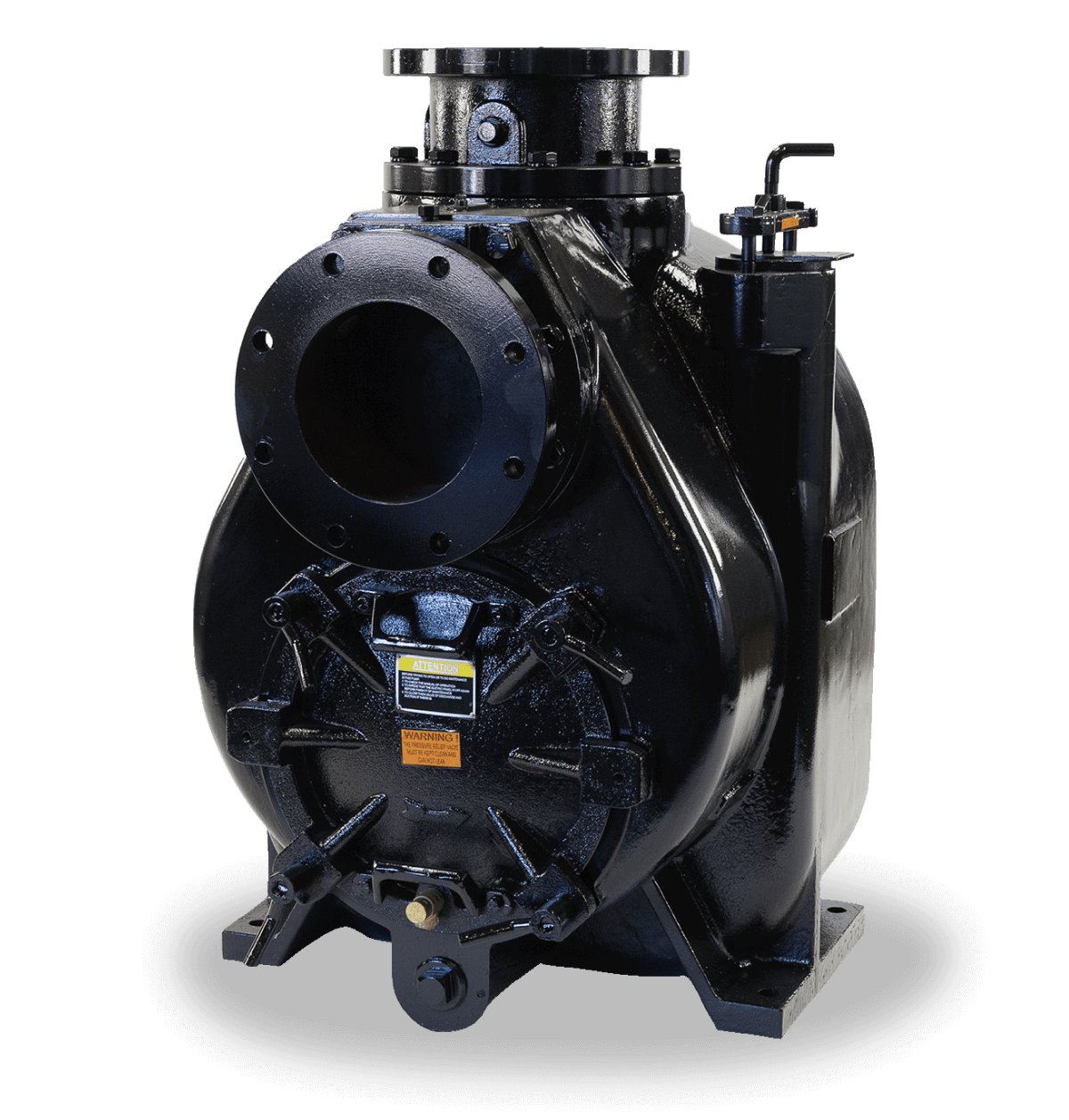

High Performance

The PL-12 pump provides high flow rates and impressive performance. Able to manage solids up to 3 inches, it's the go-to pump for a variety of high-volume pumping applications.

Removable Rotating Assembly

The PL-12 pump has a removable rotating assembly which facilitates efficient and easy maintenance, reducing operational downtime.

External Shim-Less Adjustment

The PL-12 pump is equipped with an external shim-less adjustment feature, enabling easy adjustment of impeller and wear plate clearance without complete disassembly. This helps to maintain optimal pump performance.

Multi-Vane Impellers

The PL-12 pump employs multi-vane impellers to achieve maximum efficiencies. These impellers ensure effective handling of solids and slurries, making the pump suitable for diverse demanding applications.

Replaceable Wear Plate

The PL-12 pump includes a replaceable wear plate, extending the pump's life span and reducing maintenance costs. The wear plate can be replaced without disassembling the entire pump.

Back Pull-Out Design

The PL-12 pump boasts a back pull-out design, simplifying maintenance. This design allows the pump to be disassembled for repair or inspection while leaving the casing in place in the piping system.

Automatic Air Release

The PL-12 pump features an automatic air release system during priming, ensuring smooth operation. The pump can prime and reprime fully automatically, eliminating the need for a foot valve.

Dual Protection System

The PL-12 pump incorporates a dual protection system, including a seal leak detector and a bearing temperature sensor. This feature facilitates early detection of potential issues, thereby preventing serious operational failures.

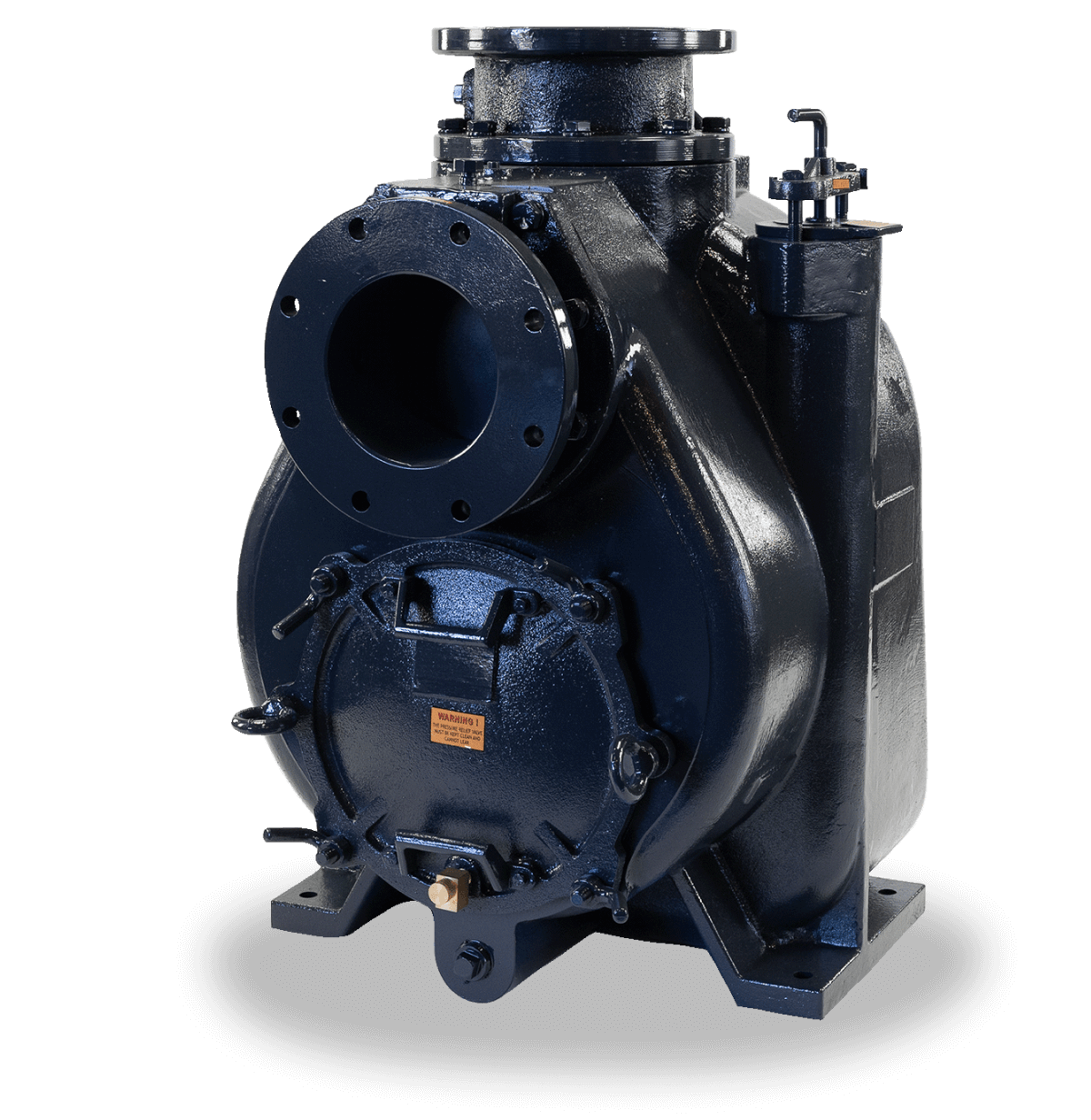

Versatile Applications

The PL-12 exceeds in serving professionals across industries such as asphalt, water & wastewater, chemical, mining, food & beverage, oil & gas, pulp & paper, electricity & power, agriculture, and general commercial industries.

Pump Data

Self-Priming Head

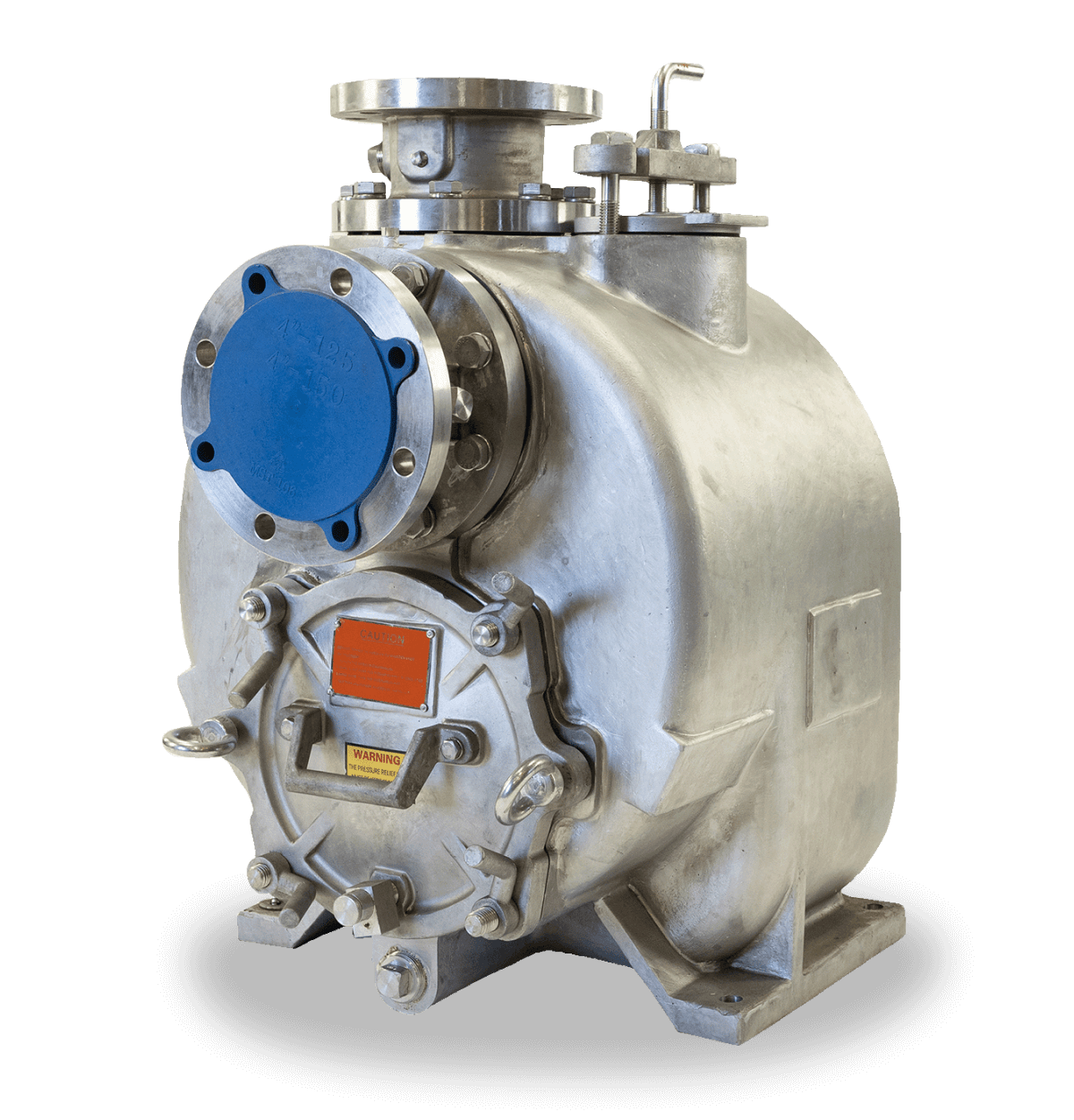

Materials of Construction

Check the net positive suction head (NPSH) before using this table

Component | STD | CI / 316SS | CI / CD4MCU | CI / ADI | CI / HCI | ADI | 316SS | CD4MCU |

|---|---|---|---|---|---|---|---|---|

Casting | – | – | A48CL30 | – | – | ADI | 316SS | CD4MCU |

Impeller | A60-40-18 | 316SS | CD4MCU | ADI | HCI | ADI | 316SS | CD4MCU |

Wear Plate | A48CL30 | 316SS | CD4MCU | ADI | HCI | ADI | 316SS | CD4MCU |

Cover Plate | A48CL30 | ADI | 316SS | CD4MCU | ||||

Bearing Housing | A48CL30 | ADI | 316SS | CD4MCU | ||||

Seal Plate | A48CL30 | 316SS | CD4MCU | ADI | HCI | ADI | 316SS | CD4MCU |

Flap Valve | Neoprene | Viton | ||||||

Impeller Shaft | ANSI4140HT | ANSI17-4PH | ||||||

Seal Sleeve | ANSI4140HT | ANSI17-4PH | ||||||

Flanges | A48CL30 | ADI | 316SS | CD4MCU | ||||

O Rings | Buna | – | Viton | – | ||||

Mechanical Seal | 316SS, Buna, Tungs/Titanium Carbide | 316SS, Viton, Tungs/Titanium Carbide | ||||||